QUALITY EXCELLENCE

Q.R.Q.C.(Quick response quick control)

Implementation of three-dimensionality and

30-minute layer-by-layer upgrade management

Implement of "red box" management for defective products

Quality kanban and daily quality reports

GENBA Walk

Weekly 6S inspection

Monthly TPM inspection, monthly results announced

Monthly quality inspection

Monthly security inspection

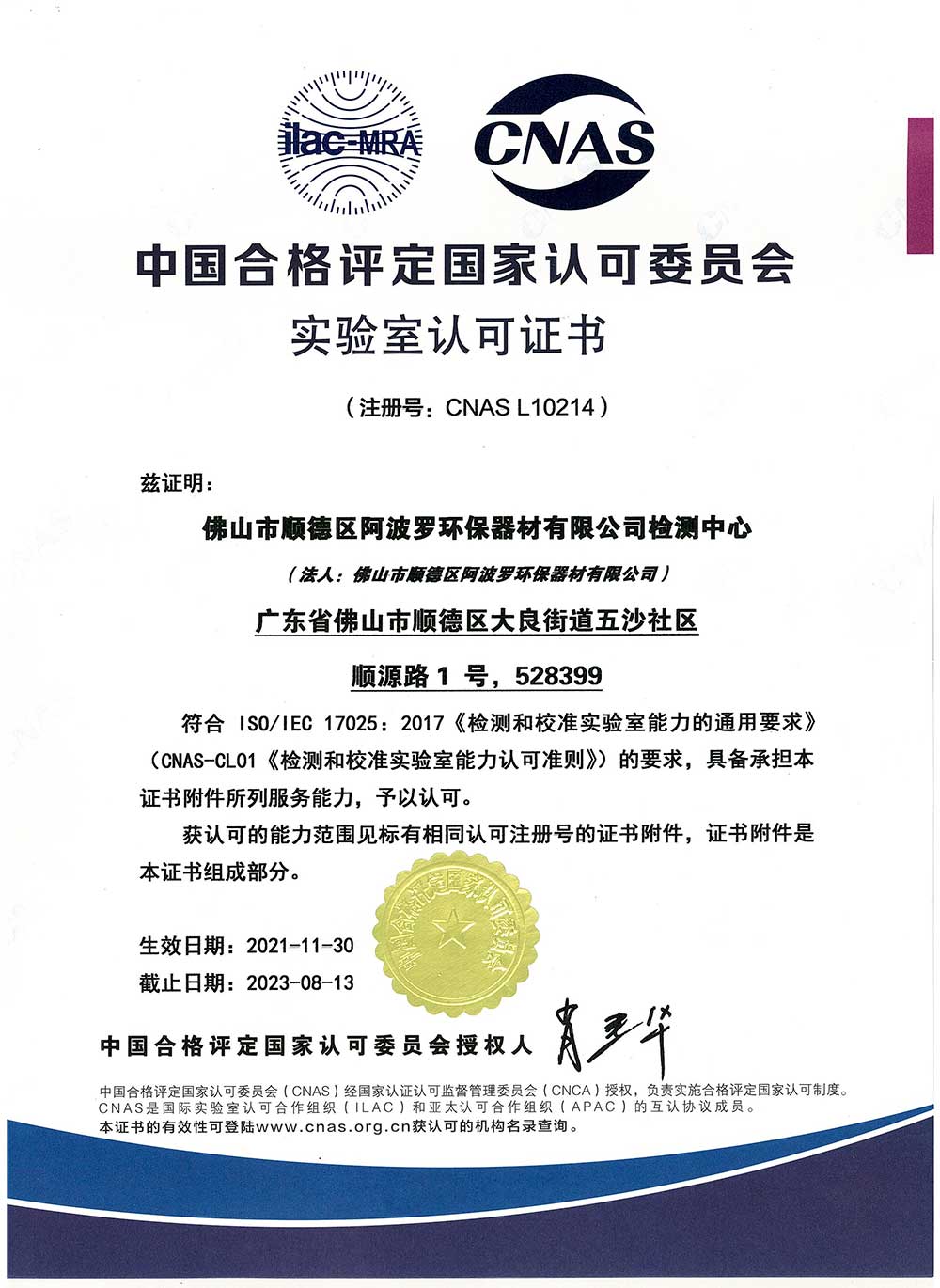

LABORATORY ACCREDITATION CERTIFICATE

Freudenberg Apollo is accredited in accordance with ISO/IEC 17025: 2017 General Requirements for the Competence of Testing and Calibration Laboratories (CNAS-CL01 Accreditation Criteria for the Competence of Testing and Calibration Laboratories) for the competence to undertake the service described in the schedule attached to this certificate. The scope of accreditation is detailed in the attached schedule bearing the same registration number as above. The schedule forms an integral part of this certificate.

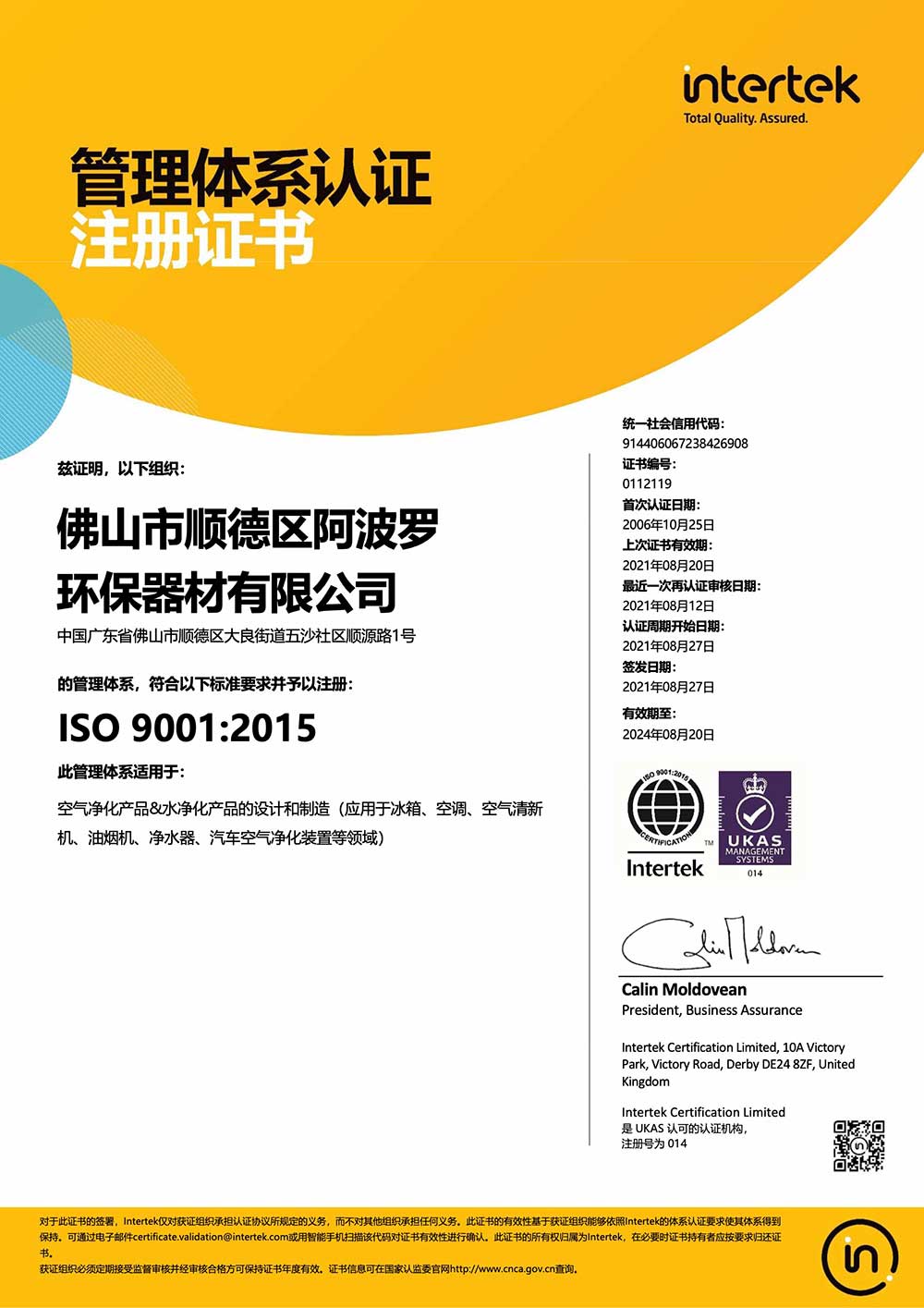

Quality Management System Certification

Freudenberg Apollo passed the ISO9001 international quality management system standards and received a certification in November 2001. Freudenberg Apollo embraces the challenge to perform at the highest levels, utilizing the finest scientific equipment, and applying sophisticated enterprise management systems. Over the years Freudenberg Apollo has actively improved internal quality management, applied risk-control management and process methods, and established a solid quality assurance system to deliver the very best quality.

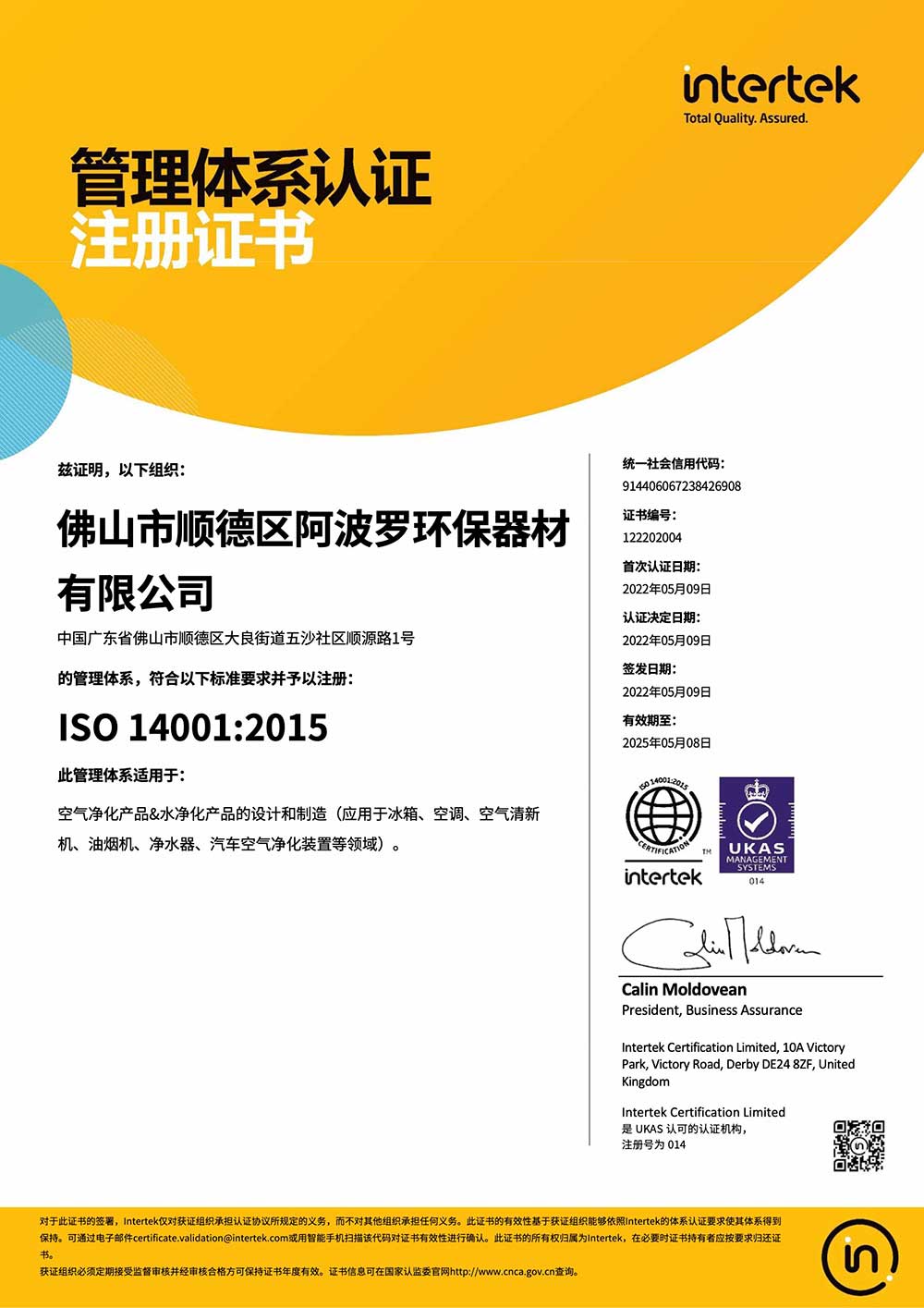

Environmental Management System Certification

Freudenberg Apollo passed the ISO14001 international environmental management system certification in January 2010. In response to global environmental pollution, serious ecological damages, ozone depletion, global warming and the disappearance of biodiversity, Freudenberg Apollo understands how important its role is in protecting and improving the environment and being a responsible global citizen.

Automobile Industry Quality Management System Certification

Freudenberg Apollo passed the IATF16949 automobile industry quality management system certification in February 2013. This helps increase the focus and assurance on quality management techniques and processes. By using APQP, FMEA, PPAP, MSA, and SPC advanced tools, continuous improvement and issue prevention can be achieved. Reducing flaws and waste and providing the best products and services to the customer is our goal.